Most contamination problems can be prevented by exercising care during the cleaning and soldering process. Care should be taken not to immerse or spray unsealed switches during flux removal. Contact E-Switch for specific soldering recommendations and specifications not found in this catalog. Generalized soldering procedures are outlined below.

Please click on the PDF to view the Soldering Profile Guidelines in a printable version.

Recommended Soldering Guidelines

HAND SOLDERING TEMPERATURES

Recommend soldering irons of 30 watt maximum with a tip temperature of 345°C (650°F) for 2-3 seconds and solder of 0.030 – 0.040 diameter.

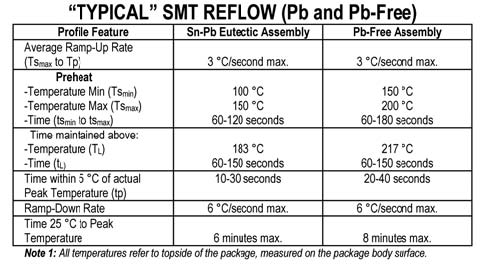

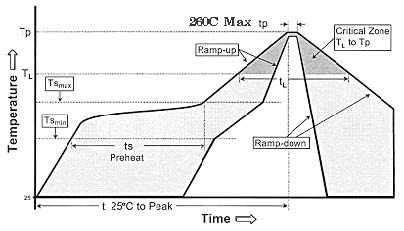

SMT RE-FLOW (LEAD AND LEAD-FREE)

Classification Re-flow Profile

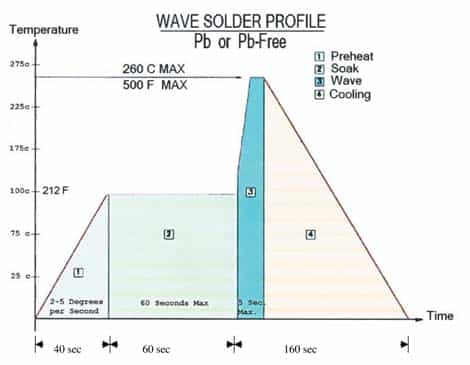

WAVE SOLDER TIME AND TEMPERATURES

When wave soldering, we recommend using a no-clean flux soldering process, rather than a process that requires washing. The fluxing process must be controlled so as not to have flux migrate inside the switch.

WAVE SOLDER

(Includes Pb-Free, max component side preheat temp-130°C)

Good venting is required. No-clean flux vapors can enter the switch if adequate venting is not available. The vapors will condense on the internal contacts and become an insulator when they solidify.

- Preheat temperature/time: Circumferential temperature of the p.c. board not to exceed 100°C (212°F) for 60 seconds.

- Soldering temperature/time: not to exceed 260°C (500°F) for 5 seconds.