When considering what switch to design into your application, it’s crucial to review all the external forces that could impact the switch’s durability and functionality. If you’re planning on implementing your switch in an environment where it’s susceptible to harsh use and rugged conditions, then you’ll need to be sure it can withstand these factors. This is especially true of switch use in demanding, high-stakes applications within the medical, transportation and industrial markets. One measure of high durability is peel off strength, but what is peel off strength, why is it important and how is it tested?

What is Peel Off Strength?

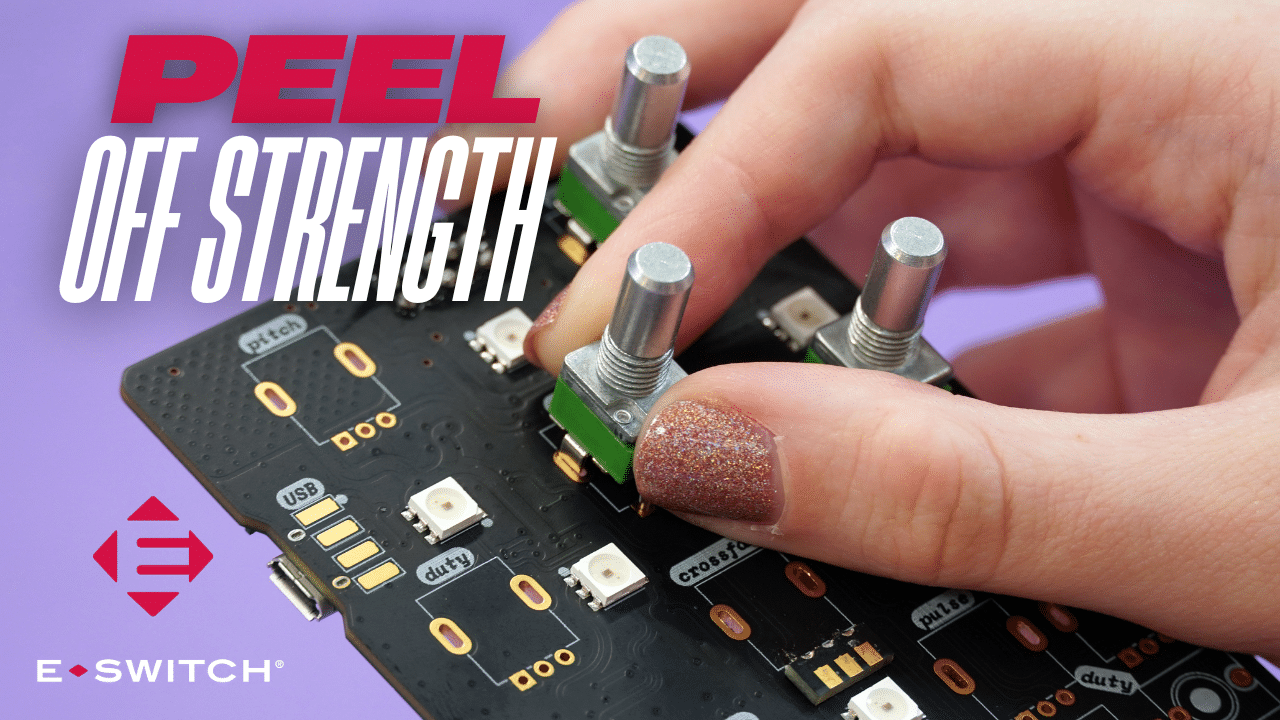

Surface mount technology (SMT) allows you to attach components to a printed circuit board (PCB). The process begins with applying solder paste to the PCB’s surface using an iron. The solder paste is a mixture of tiny metal balls and flux, which helps the solder adhere to the surface. The solder melts and flows around the component leads, creating a strong mechanical and electrical connection. This process allows for high-volume manufacturing with consistent quality and accuracy.

Peel off strength is the measured strength at which a switch would be sheared off from a PCB due to a high force or impact. Tactile, tactile dome, slide, pushbutton, rotary and DIP switches are all frequently surface mounted on PCBs to make or break electrical connections between contacts. They are small, reliable and offer cost savings during the manufacturing process, so appropriately selected switches (electrical rating, life rating, size) ultimately result in higher quality electronic devices

Various mounting constructions and methods can enhance peel off strength. For example, gull wing terminals, J-Leads, bosses and PCB cutouts will improve the operating part’s strength, while edge-mounted switches also typically have a focus on delivering a higher peel off strength.

Why is Peel Off Strength Important?

Switches are an essential component of modern electronic devices, providing reliable and compact switching capabilities. PCB switches allow electricity to flow with less resistance. They are made of highly conductive materials to provide a lower level of electrical resistance. The bonding between the switch and board is absolutely critical for various industries, including the medical, industrial and security markets.

How is Peel Off Strength Tested?

Peel-off strength testing for electromechanical switches involves measuring the force required to detach the switch from its mounting surface. This test helps ensure the durability and reliability of the switch in various applications.

- 90-Degree Peel Test: The switch is peeled off at a 90-degree angle to the mounting surface. This method is often used to test the adhesion strength of the switch’s solder joints or adhesive backing.

- 180-Degree Peel Test: Similar to the 90-degree test, but the switch is peeled off at a 180-degree angle. This method provides a different perspective on the adhesion strength.

- T-Peel Test: This test involves peeling the switch in a T-shaped configuration, which helps measure the force required to separate two bonded surfaces.

- Shear Test: Shear tests can also be used to measure the strength of the bond between the switch and the mounting surface by applying a parallel force.

These tests are usually performed using specialized equipment like force gauges and test stands to ensure accurate and consistent results.