What is a Rocker Switch?

Rocker switches are commonly used as an on/off switch that rocks (rather than trips) when pressed, meaning the rocker opens or closes the circuit. So one side of the rocker switch is raised while the other side is depressed, much like a seesaw or rocking horse.

It consists of a rectangular or square-shaped body with a hinged actuator (the “rocker”) that pivots around a central axis. When one side of the rocker is pressed, it makes electrical contact with one set of contacts, while pressing the other side makes contact with a different set of contacts.

What Are They Used For?

They’re very versatile and can be found in a wide range of applications, including:

- Household appliances: They’re commonly used in appliances such as lamps, fans, coffee makers and toasters to turn them on and off.

- Electrical equipment: They’re used in a variety of electrical equipment and devices, including power tools, computer peripherals and audio equipment.

- Automotive: They can be found in vehicles to control functions like lights, wipers and power windows.

- Industrial machinery: In industrial settings, they’re used to control the operation of machinery and equipment.

- Marine applications: They’re often used on boats and ships to control various electrical systems and equipment.

- HVAC systems: They’re used to control the operation of HVAC systems, including fans, heaters and air conditioning units.

- Electrical panels: They’re sometimes used in electrical control panels to manage the flow of electricity within a building or facility.

Pros & Cons

Rocker switches are known for their ease of use as the actuation is typically intuitive, and they often provide a satisfying click or tactile feedback when activated. They come in different sizes, colors and styles, making them suitable for a wide range of uses. They’re also known for their durability and reliability. They can withstand a significant number of actuations and are resistant to wear and tear.

However, since rocker switches are primarily designed for simple on/off functions, they may not be suitable for applications that require more complex or multi-position switching. Since they’re typically binary in their operation, they may not be well-suited for applications that require precise adjustments or variable control.

What’s the Difference Between a Rocker Switch and Toggle Switch?

The main difference between rocker switches and toggle switches is the way they are actuated and the associated physical design.

A rocker switch is actuated by pressing one side of the switch to open a circuit or the other side to close it, typically by rocking the switch back and forth. It has a pivoting actuator that moves around a central axis. A toggle switch, on the other hand, is actuated by flipping a lever or handle, which moves in a vertical or horizontal motion. It can be switched on or off by moving the lever in one direction or the other.

Rocker switches are ideal for simple on/off functions and are often used for applications that require clear visual and tactile feedback. Toggle switches offer more versatility, supporting both on/off and multi-position switching, making them suitable for various control applications.

The choice between them depends on the specific needs of the application and the user’s preference for their operation and appearance.

E-Switch Rocker Switch Offerings

E-Switch offers a range of rocker switches, from miniature size with low current ratings to industrial use switches with high power ratings and with horsepower ratings. Several switches provide an IP rating of IP67, IP55 or IP54, depending on the switch series.

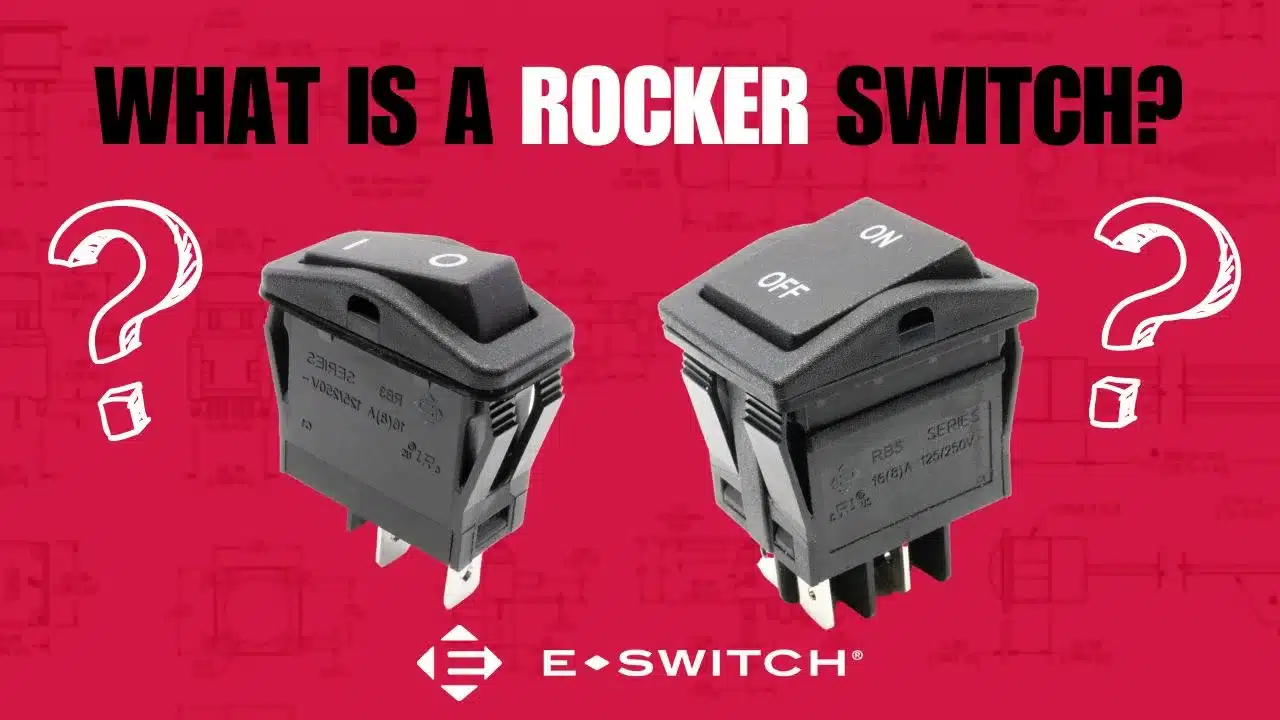

Most recently, E-Switch launched the RB3 Series Illuminated Rocker Switch and RB5 Series Rocker Switch.

Panel mount installation is most common, however, a few E-Switch rocker series provide PC mount options. Additional options include non-illuminated or illuminated, as well as actuator shapes such as rectangle, round, oval and paddle-style actuators.

Learn more about E-Switch’s rocker products in the blog post linked below!