As you search for the best switch for your application, you might decide on a tactile switch (tact switch). Tact switches leave a small footprint and are commonly used in consumer electronic devices, but how exactly do these switches connect to the product? In this article, we’ll take a look at the two types of leads that are available for tact switches: J-lead vs gull wing.

J-Lead vs Gull Wing Leads

First, let’s look at what they both have in common. These leads are used for surface mount switches. Surface mount means the leads of the switch stay on the surface of the printed circuit board (PCB), which the switch is connected to. This sets them apart from through hole switches, where the leads go through the printed circuit board.

Now, let’s learn how to tell a J-lead apart from the gull wings. If a switch has a J-lead, this means the leads curve snuggly underneath the switch. As the name suggests, the leads are curved in a way that looks like the letter ‘J’.

J-leads are sturdier than gull wings. Since the leads go underneath the switch, they’re higher than gull wings too.

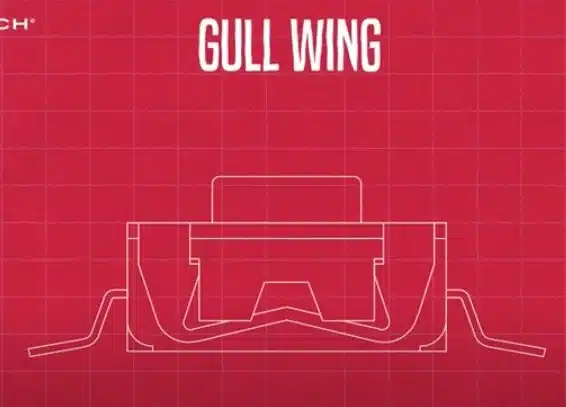

If a switch has a gull wing, this means the leads spread away from the center of the switch. They extend out slightly, then down and then out again. If you look at the way the leads extend from the switch, it might remind you of the wings of a bird — like a seagull for instance.

Gull wings are more fragile than J-leads and take up a wider amount of space.

J-Lead Pros

Increased Thermal Performance: J-leads often provide better thermal performance than gull wing leads. The extended leads help in dissipating heat more efficiently.

Reduced Shadowing Effect: They can reduce the shadowing effect, which occurs when one component casts a shadow on another, potentially affecting soldering.

Improved Mechanical Stability: The J-shape leads tend to provide better mechanical stability, making the component more resistant to mechanical stresses.

J-Lead Cons

Challenging to Hand Solder: J-leads can be more challenging to hand solder due to the shape of the leads. Special attention and skill are required to ensure proper soldering without causing damage to the component.

Higher Cost: The manufacturing process for J-leaded components can be more complex and costly compared to gull wing leads.

Gull Wing Pros

Ease of Manufacturing: Gull wing leads are relatively easier to manufacture, making them a cost-effective choice for mass production.

Simpler Hand Soldering: Gull wing leads are generally easier to hand solder, especially for hobbyists or small-scale production.

Gull Wing Cons

Less Efficient Thermal Performance: Gull wing leads may not dissipate heat as effectively as J-leads. This can be a concern in applications where thermal management is critical.

Shadowing Effect: Gull wing components can exhibit a shadowing effect, where one component casts a shadow on another during the soldering process. This may affect the soldering quality.

Lower Mechanical Stability: Gull wing leads may be more susceptible to mechanical stresses, potentially leading to damage or failure.

In summary, the choice between J-lead and gull wing terminals depends on the specific requirements of the application. J-leads are often preferred in situations where thermal performance and mechanical stability are crucial, while gull wing leads are chosen for their simplicity and cost-effectiveness, especially in applications where these factors are less critical.